Power Your Home With the Best Backup Generator

Main Components of a Generator

Although there are many backup generators of different makes and models, they all contain the same essential parts. Let’s look into how each works:

- Fuel System

The fuel system is where you supply your generator’s fuel source, whether diesel, natural gas, or propane. It includes a fuel tank, fuel pipes, pumps, filters, and regulators. Fuel goes to the engine through the fuel line, while excess fuel not needed in the engine goes back to the tank through the return pipe.

The pump moves the fuel throughout the tank, connectors, and engine. Filters are placed within the system to ensure the fuel that goes into the engine is free of debris and contaminants. - Engine

The engine is the core of every standby generator unit. Its primary role is converting energy from the fuel source into mechanical energy. Engines are built to be durable and capable of producing the maximum streams of electricity possible. - Alternator

The alternator transforms mechanical energy into the electricity we need through electromagnetic induction. This device consists of many complex parts, but the most crucial one is the rotor, which is a shaft with several magnets.

The rotor moves around the stator, a stationary part with electrical conductors. This rotation creates a magnetic field that forces electrons to move and produces the generator’s alternating electrical current. - Voltage Regulator

Every generator needs a regulator to monitor and keep the electricity output’s voltage at the proper levels. This device ensures your unit can meet your energy requirements and accommodate varying voltage ranges of multiple appliances or machinery. Without one, the generator could suffer voltage fluctuations, which can compromise the functionalities of the unit and the equipment connected to it. - Lubrication System

Generators have machine parts that constantly move and create friction. For this reason, each unit must have lubricant, like oil or specialized fluids, to ensure smooth operation. The system coats the generator’s metal parts with a thin layer of clean lubricant to:

• Prevent friction resistance on metal surfaces

• Reduce heat generated by the engine

• Form seals between parts

• Keep the engine’s interior clean

• Protect the components from mechanical wear and tear - Exhaust and Cooling Systems

Generators are prone to overheating when in use. A fixed cooling system regulates the temperature within (whether by liquid or air) and gets rid of excess heat through the exhaust. Aside from pushing out hot gases, the exhaust system works with the air intake system to circulate fresh air in the unit. - Battery

This energy storage device delivers power to the cranking motor during machine startup. When the engine’s electrical load exceeds the supply from the charging system, the battery works to provide additional power needed. Moreover, it helps stabilize and prevent voltage spikes from damaging the electrical system. - Control Panel

The switches and buttons for operating the generator are in the control panel. It’s your reference for the gauges, parameters, and details like fuel level, voltage, and coolant temperature. - Automatic Transfer Switch (ATS)

This device is the main link between the standby generator and your home. During outages, it disconnects a house’s main electrical system from the power grid and immediately connects it to the generator. - Main Assembly Frame

The main assembly frame or enclosure houses all of the components above. Although the designs may vary per brand, they generally come in two types: weatherproof and sound-attenuated assembly frames. Weatherproof frames protect the generator from the elements, harsh climates, and moisture. Meanwhile, sound-attenuated types focus more on reducing the unit’s noise.

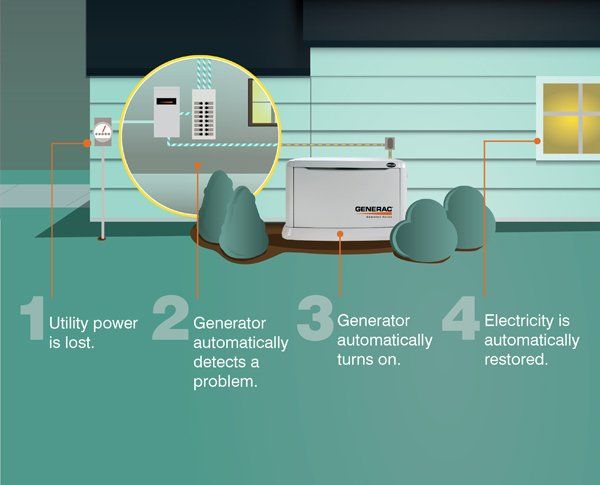

How Standby Generators Work

Generators automatically start up as soon as the power in your primary source of electricity gets lost. The ATS switches the power source to the generator while the control panel signals the engine and alternator to begin producing electrical energy.

Once the voltage regulator has stabilized the current, the electricity is distributed to the circuits that connect back to the property’s electrical system. Electricity is automatically and immediately restored—it’s that simple. The unit will automatically stop operating and cool down once it detects that the main power source is back and stable again.

Have Power at the Ready Anytime

With a generator from HMC Generators, you can secure peace of mind during power outages and emergencies. Discuss your requirements with us, and we’ll guide you from selecting the best backup generator to installing and maintaining it. Book an appointment today to get started.